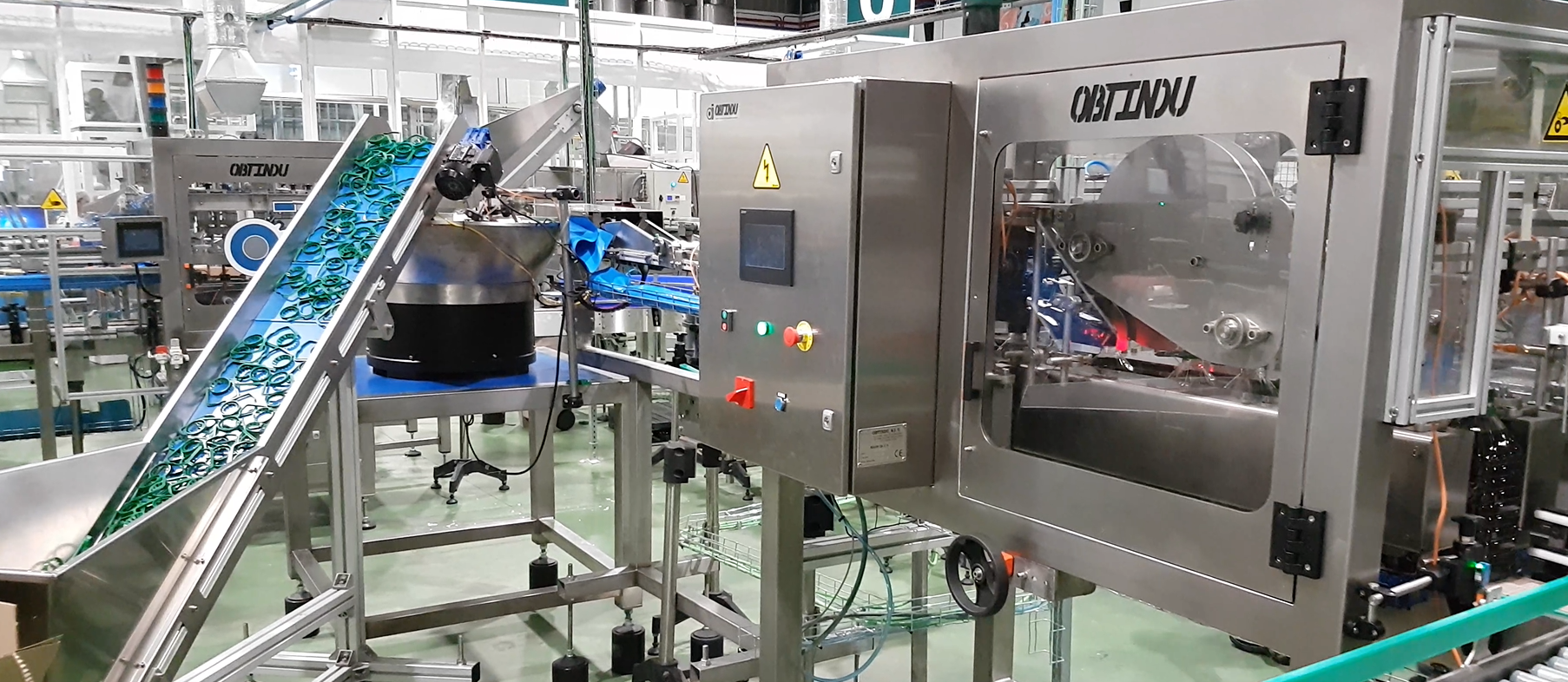

Solutions for Blow molding and Bottle packaging

We design, manufacture and integrate into your production line; Boosting your efficiency.

Thanks to more than 25 years of experience in the development and manufacture of machines and packaging lines for PET and HDPE containers, you can find a wide range of the following equipment;

- End of line with palletizing systems for empty or full containers

- Depalletizing system for empty bottles

- Handle applicator for full or empty bottles, with a clean and fast insertion of the handle for productions reaching up to 12,000 BPH

- Bagging machine for bottles that inserts empty containers into bags forming compact packages

- Automatic pallet stacker-doser

- PET/HDPE bottle conveyor, both empty and full, adapting them to your needs.

- Pallet conveyor

- Dosing table for containers, etc.

- Equipment integration; strapping machine, wrapping machine, labelling machine, etc.

The main feature of our equipment is versatility, in that they adapt to a wide range of packaging formats through extremely fast and simple format changes. Robust equipment, easy to use, and fast amortization, which adapts to your needs will allow you to save money and time, with optimal operation in your production line.

All this with the best quality/price ratio in the market and with the most interesting technological advantages.

END-OF-LINE AUTOMATION

"Turnkey project"

We design, manufacture, and integrate the best solution for end-of-line automation. We excel in the blow moulding of containers and liquid packaging (oil, water, soft drinks, etc.) and offer an optimal solution for any industry.

We are experts in the automatic handling of empty plastic containers, such as palletizing, depalletizing, transport, etc.

In end-of-line palletizing, we adapt to the customer's needs and provide solutions to any limitations that may appear in the project, such as limited space in the installation, greater or lesser autonomy of the line, flexibility, etc.Diseñamos, fabricamos e integramos la mejor solución para la automatización del final de línea. Destacamos en el sector del moldeo por soplado de envases y el envasado de líquidos (aceite, agua, refrescos..), además de ofrecer una solución óptima a cualquier tipo de industria.

Describe some quality or feature of the company. Write a short paragraph about it and choose an appropriate icon.

Bagging of empty bottles

Describe some quality or feature of the company. Write a short paragraph about it and choose an appropriate icon.

Describe some quality or feature of the company. Write a short paragraph about it and choose an appropriate icon.

Conveyors

Describe some quality or feature of the company. Write a short paragraph about it and choose an appropriate icon.

EQUIPMENT FOR INDUSTRIAL PROCESSES WITH EMPTY OR FULL CONTAINERS

LATEST TECHNOLOGIES ADAPTED TO MARKET DEMANDS

ROBUSTNESS AND PRECISION, CHARACTERISTICS OF OUR EQUIPMENT

QUICK TECHNICAL SUPPORT AND A LARGE STOCK OF SPARE PARTS

Save Time

Our machines stand out in the market for being able to make packaging format changes quickly, by incorporating the latest technologies, avoiding unproductive stops in the production line.

Technical Service

Our warehouse has a large stock of spare parts available for our clients, as they needs them, thus avoiding machine shutdowns in their facilities. We'll take care of a quick delivery to your premises, optimizing the logistics process for the faster delivery for the low cost possible.

Quick and Reliable Service

In OBTINDU we have a team of highly-qualified professionals to guarantee a high-quality technical assistance service, in order to provide a quick and effective response.

Grow your Business

Our equipment is designed to provide your production line with greater effectiveness in terms of cost savings and quality of the final product. Solutions with an excellent quality/price ratio, achieving a rapid return on investment.

We are at your disposal for any questions you want to ask us. For us, it is essential to provide you with good service and attention.

OBTINDU IDENTITY

OBTINDU S.L.

P.I. La viña, Av. de la Industria, 3

La Algaba (Sevilla) España 41980